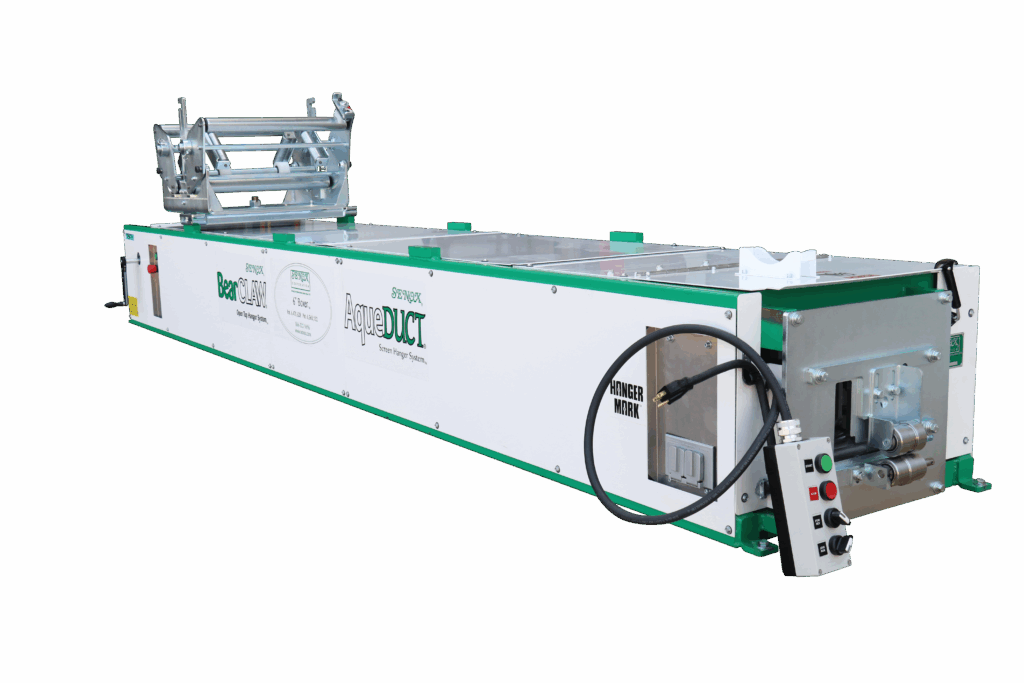

As a gutter contractor, your seamless gutter machine is vital. We want to ensure your satisfaction throughout the buying process.

Our staff will help you select the right machine and setup options. We conduct comprehensive inspections and complete setup before delivery. Our expert technicians will guide you through operating procedures and maintenance questions and will mount your machine on a truck or trailer at no additional cost.

Senox provides scheduled maintenance and adjustments at our branch locations. When you buy from us, you can trust that you’ve chosen the best equipment, service, and support in the industry.

Machine Service

Our knowledgeable team is here to help with all seamless gutter machine brands! Your local Branch Manager will have more details and can help you reserve an appointment.

5″ K-Style

Compact Gutter Machine

Base Machine Dimensions

- Length: 80″

- Width: 24″

- Height: 17″

Weight

- 802 lbs

Speed

- Approximately 35-40 feet per minute

5″/6″ Combo

Compact Gutter Machine

Base Machine Dimensions

- Length: 105.5″

- Width: 24″

- Height: 17″

Weight

- 962 pounds

Speed

Approximately 35-40 feet per minute

6″ K-Style

Compact Gutter Machine

Base Machine Dimensions

- Length: 105.5″

- Width: 24″

- Height: 17″

Weight

- 961 pounds

Speed

- Approximately 35-40 feet per minute

6″/7″ Combo

Base Machine Dimensions

- Length: 164″

- Width: 24″

- Height: 17″

Weight

- 1,452 lbs

Speed

- Approximately 35 feet per minute

7″ K-Style

Base Machine Dimensions

- Length: 167″

- Width: 24″

- Height: 17″

Weight

- 1,452 lbs

Speed

- Approximately 35 feet per minute

6″ Half Round

Base Machine Dimensions

- Length: 162″

- Width: 33″

- Height: 19″

Weight

- 1,753 lbs

Speed

- Approximately 35 feet per minute

6″ Boxer

Base Machine Dimensions

- Length: 139.75″

- Width: 24″

- Height: 17″

Weight

- 1,200 lbs

Speed

- Approximately 35-40 feet per minute

Half Round Wedger

Base Machine Dimensions

- Length: 164″

- Width: 34.5″

- Height: 51″

Weight

- 2,000 lbs

Speed

- Approximately 35 feet per minute

Hanger Mark

The Hanger Mark add-on for all Senox Barracuda gutter machines is an innovative way to help you spend less time on your current job, so you can move on to the next one. Now, instead of having to measure and mark your hanger intervals by hand, your gutters come off the machine already indented on the inside, back at 8″ intervals to indicate proper hanger placement. It literally could not be any easier! Your clients will never see it, but you’ll see big returns since time = money.

Polyurethane Drivetrain

- Eliminates the need to load coil prior to transportation (less material waste)

- Eliminates slippage from cold weather and condensation

Structural Steel Frame

- Welded steel frame

Electrical and Control System

- Push button control safety wiring

- Entrance and exit control selector switch jog run

- 3/4 HP, 110 volt, single phase motor, 13.6 amps

Warranty

- 3 Years Parts and Labor

- 1 Year Electrical

.002 Hard Chrome Plated Steel Forming Rollers

- Rollforms all standard metals with minimal or no adjustment

- Free-floating forming rollers produce less pressure and allow for more product & uniformity

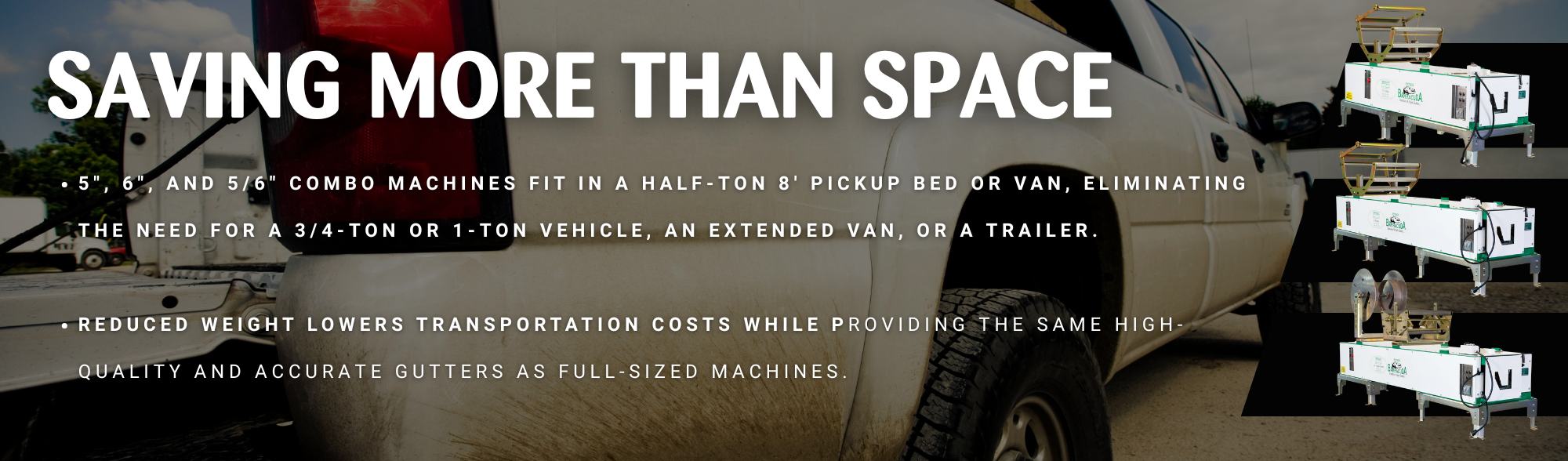

- 5″, 6″, and 5/6″ combo machines fit in a half-ton 8′ pickup bed or van, eliminating the need for a 3/4-ton or 1-ton vehicle, an extended van, or a trailer.

- Reduced weight lowers transportation costs while providing the same high-quality and accurate gutters as full-sized machines.